Introduction

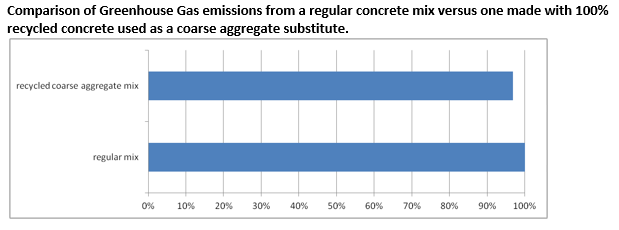

The GHG emissions associated with virgin aggregate (rocks) are due to a combination of combustion emissions from transportation and material extraction. If using recycled aggregate, which is old concrete crushed to size, GHG emissions are reduced due to the avoidance of mining, crushing, and transporting virgin aggregate. Figure 4 below shows the GHG savings of using 100% recycled aggregate in a typical concrete mix. One can see that the GHG savings are real but they plateau at about a 3% reduction. Additionally, current ASTM limits on structural concrete limit recycled coarse aggregate to 10%. While project specific testing can permit larger uses of recycled aggregate, using 100% recycled coarse aggregate would be very rare. Thus, the carbon reduction benefits of this strategy are likely overestimated. The use of recycled aggregate, however, has benefits beyond carbon reductions. Most notably, recycled aggregate conserves a non-renewable resource that is mined from land and waterways and can have environmental impacts far beyond carbon impacts. Therefore, while recycled aggregate should not necessarily be a primary strategy for reducing the carbon content of concrete mixes, it should remain a component of public purchasing when appropriate. Additionally, in remote areas, the transportation of aggregate can be a large environmental and financial cost, which could drive the use of recycled aggregate even further.