Introduction

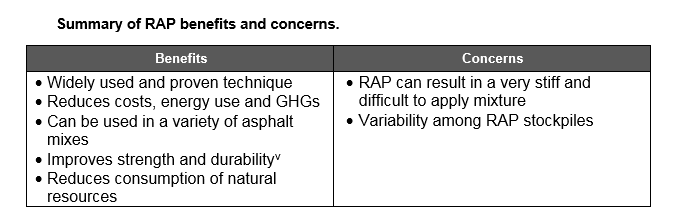

Reclaimed asphalt pavement is a material, not a process like warm mix asphalt concrete (WMAC), and thus can be used with either hot mix asphalt concrete (HMAC) or WMAC. RAP is the recycling of asphalt pavement from existing roadways or parking lots into new asphalt through milling it into virgin sized aggregate particles and reheating the material into a new batch of asphalt concrete. Since RAP still contains the original binder, using RAP can lower the need for virgin materials – both binder and aggregate, cutting costs and GHG emissions.

RAP Specification best practices include:

- Be aware of the availability and materials properties of RAP.

- Adopt a specification that achieves the desired quality with the materials available in the area.

- Require quality control and quality assurance to verify the quality of the materials.

As mentioned in the warm mix section, selecting the appropriate mix design and specifications for the conditions is necessary regardless of the type of asphalt pavement used. Oftentimes, perceived failures of materials can be traced back to mix design selection rather than the materials themselves.